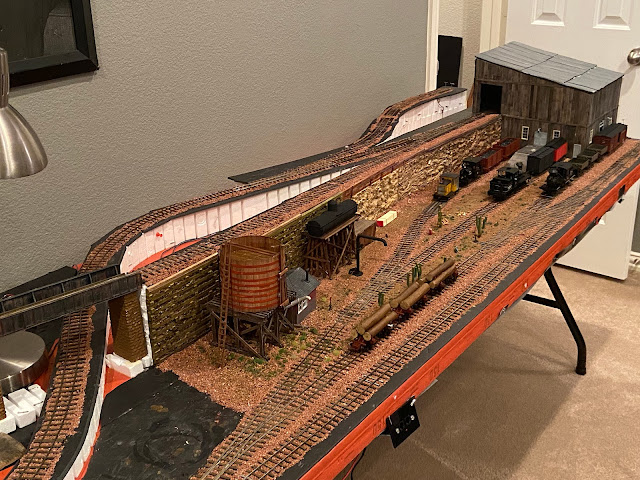

The Gump Stump On30 Layout

B.T.S. McCabeWater Tank, Woodland Scenics yard office, Bachmann 2 Truck Heisler, Micro Engineering Code 70 track and turnouts

http://www.btsrr.com/bts7489.htm

Scratch Built Stamp Mill in the background

Picture with the old Chooch Retaining walls, they were okay but I preferred a scratch built one shown above, made from styrene. It gives more depth for a wall this size.

Loading Dock for the Stamp Mill

Lighted Interior

Older Picture

I have 2 Tam Valley Hex Frog Juicers, great product if you want live frogs.

https://www.tamvalleydepot.com/products/dccfrogjuicers.html

Full Layout Pictures (Very early on)

Midway on the warehouse build, this is a Banta Modelworks kit.

https://www.bantamodelworks.com/

Completed Warehouse Build

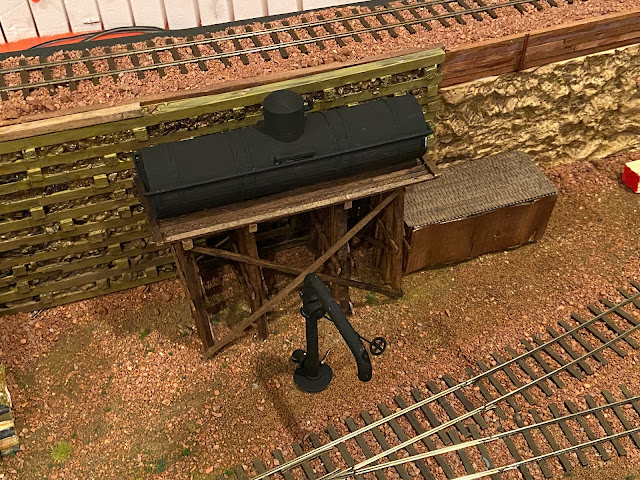

Below- Locomotive Oil facility, oil tank was 3D printed, the platform was leftover lumber materials, and the oil column was scratch made using Plastruct items.

Here I mocking up the area using foam, Cripplebush rubber rocks, and some 3D printed western desert rocks as an experiment. I was floored by how well they are printing out, and the quality of the files are outstanding.

3D Printed Stock